Staroguard Ultra Protek :Exterior wall coating 2 coat

Product Description :Its unique surface cross-linking feature coupled with Nano performance enhancers contribute to its outstanding mechanical, anti-carbonation properties with long lasting durability in severest climatic conditions. A tough high grade, solvent free, single component; acrylic based product for the protection of concrete, mortar, masonry, natural stone and wood against aggressive environmental attack

Uses:

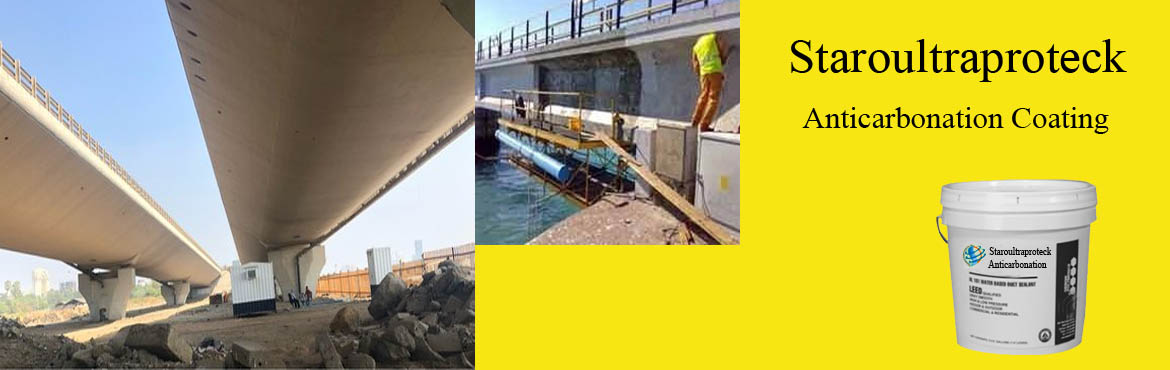

Used for the protection of concrete facades, walls, bridge parapets, balconies, columns, beams etc against carbonation of concrete

Features :

• Effective Waterproofing-The superlative waterproofing capabilities of the Staroguardultra proteck forms an effective barrier against water penetration.

• Crack bridging - Staroguardultra proteck has significantly higher elongation and comes with unique fibre reinforcement thereby offering a unique crack bridging ability of upto 2mm.

• Superior Clean ability- Better ease to clean common streaks of exterior surfaces ensuring your walls look fresh for a longer period of time.

• Structural protection Staroguardultra proteck has excellent CO2 diffusion (carbonation) resistance & prevents the corrosion of rebar within the concrete matrix, leading to superior structural protect

• Environmentally Responsible :This product has VOC less than 30 Grams per litre which conforms to international VOC specifications and is free from hazardous materials like heavy metals (lead, mercury, arsenic, chromium, cadmium, arsenic) and toxic materials (carcinogen, mutagen, reproductive toxins, APEOs).

• Permeable to vapour – Does not allow moisture to build up behind the product stopping damage to coating by osmosis

• Available in a wide colour range – Can match the aesthetics and functional requirements.

• Materials that create a hydrophobic surfaces on concrete (can be used as . primers to give double the protection – Double the protection without compromising adhesion to the surface

Typical Physical Properties:

• Aspect : Viscous Dispersion

•Consistency: : Thick paste

•Density: : 1.35 ± 0.05 kg/litre

•Volume Solids : 46%

• Application temperature : 5°C to 40°C

• DFT at 0.9 Kg/m² : 300 μ

• Touch dry : 1 Hour at 25°C

• Recoatable: : 4 Hours at 25°C

• Full Care : 7 Days

• Drying time : Surface dry time 30 min

•Flash point IS101/1987 Part 1 Sec 6 :> 600C

• Elongation, (ASTM D 638) : >300%

• Tensile strength, (ASTM D 638) : > 2.5 MPa

• Adhesion, (AS 1580 408.2) : 4/5 (excellent)

• Dirt pickup (AS 1580 481.1.4, 12 months), on a scale of 0-5 : 1 (0 = 'no dirt retained')

• Water vapour permeability (DIN 52615) : 26.0 g/m2/24 Hours

• Chloride ion diffusivity : 4.98 x 10-10 cm²/s

• Reduction in chloride ion ingress : 97% at 28 Days

• CO2 diffusion resistance Equivalent air layer thickness, R : > 50m

• Appearance after 2000 hr accelerated weathering : No colour change or chalking

Application :

New masonry and concrete should be at least 14 days old before treatment and with moisture level in substrate below 7% by volume.

Surface preparation :

Correct substrate preparation is critical for optimum performance. The surface to be treated must be thoroughly cleaned. Remove all traces of formwork, release agent, grease, efflorescence, laitance, algae or other contaminant that may prevent proper adhesion. Remove organic materials by scraping, brushing or high pressure water cleaning. Spores must be treated with a suitable fungicide sterilizing agent and carefully rinsed.

On non-decorated concrete surface containing blow holes and/or minor irregularities, and on some rough rendered or dashed surface. Cracks wider then hairline should be patched using Crackfill or sealed using acrylic caulk before treatment.

Priming : Prime the surface using Stargouard prime (WB) as primer. Allow the primer to dry for 2-3 hr (at temp. >25ºC) before applying Staroguard ultra proteck At lower temperatures, allow a longer time to dry.

Mixing : Staroguard ultra proteck is ready for use. Stir (do not dilute) to obtain a uniform mixture before use. ventilated area, away from heat, direct sunlight, sparks and children. It contains inflammable solvents. Handle with care. Mix resin and hardener as per the ratio. Use the mix solution within the pot life time.

Application

Apply Staroguard ultra proteck in one coat using roller to achieve a wet film thickness of 650μ or in two coats each of 325μ WFT using roller or brush, with the second coat applied 2 – 4 hrs after the first and at right angle to it. The prepared sub state must be air-dry when the first coat is applied. Where a textured finish is required use a medium nap roller to apply the product and over roll with a textured roller to give the desired finish in one direction only.

Only apply Staroguard ultra proteck when the ambient temperature and substrate temperature are at least 5ºC, and will not fall below 5ºC with-in 24 hours. To avoid condensation which influences the adhesion negatively, surface temperature during application should be at least 3ºC higher then the dew point.

Shelf life :

Store under cover, out of direct sunlight and protect from extremes of temperature. In tropical climates the product must be stored in an air conditioned environment.

Shelf life is 12 months when stored as above.

Coverage :

Store under cover, out of direct sunlight and protect from extremes of temperature. In tropical climates the product must be stored in an air conditioned environment.

Shelf life is 12 months when stored as above.

Health Precaution :

Observe reasonable care and employ ordinary hygienic principles such as washing the hands with soap and water before eating. It is recommended to wear gloves, goggles and nose masks while application. Incase of splashes on the skin, dampen the cloth with thinner and wipe the hands with the cloth. Wash then with soap and water. Dried film is non toxic. In case of contact with eyes, rinse with plenty of water and seek medical advice. In case of continuous exposure to vapour, the applicator should be immediately moved to get fresh air.

| Download to Safety Data Sheet |