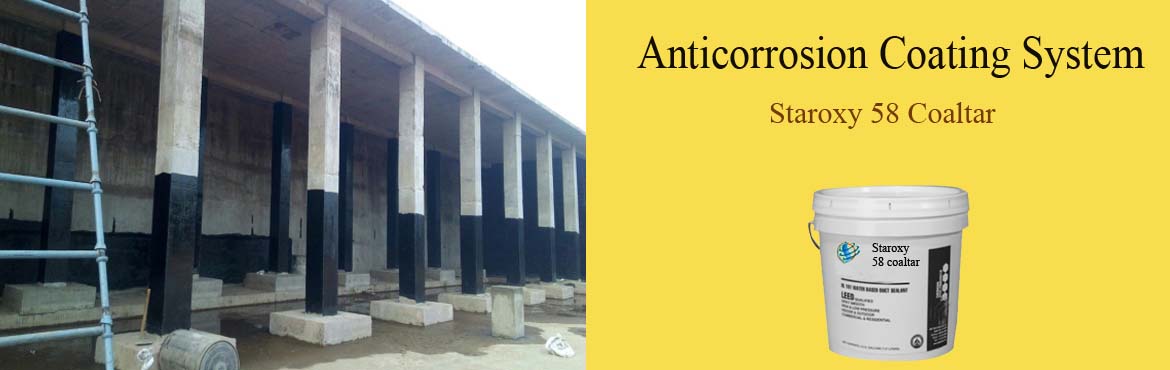

Staroxy 58 ( Coaltar Epoxy ): ANTI CORROSIVE COALTAR EPOXY SYSTEM EPOXY RESIN / COALTAR HARDENER

Product Description :Chemical industries like fertilizer, paper, textile face more problems of water leakage than other industries. Similarly newly constructed houses, balconies, roofs are also susceptible to water leakage's. The problem becomes more severe in hill – station where rain fall is too high. Water leakage's create dampness in the wall and corrosion to steel. This is not only temporary problem but a problem which has got permanent effect on the construction. Use of Epoxy Resin / Coaltar Hardener ( Coaltar base epoxy system ) does not only stop the further leakage's but also strengthens the existing structure.

TYPICAL PROPERTIES :

RESIN : EPOXY RESIN

Color and appearance - Pale clear

Viscosity @ 25oC by Brookfield - 9,000 – 12,000 cPs

Epoxide equivalent - 180 – 210

Hydrolysable chlorine content - Maximum 0.5%

Shelf Life - 12 months at room temp.

in original sealed condition

HARDENER : COALTAR HARDENER

Color and appearance - Black

Viscosity @ 25oC by Brookfield - 4,000 – 6,000 cPs

Shelf life - 12 months at room temp in original

Sealed container.

APPLICATION :

To get improved adhesion it is necessary to clean the surface before applying system in such a

way that no traces of oil, dust remain on it. Plenty of water and mild acids are suggested.

Surface should be made rough by coarse wire brush or by sand blasting.

Apply Resin / Hardener mixture to get good adhesion. It is necessary to give minimum two

coats ( wet on wet ). If the problem is severe then additional third coat also may be given.

Coverage m. s. surface - 4/5 sq. mtr. Per kg mix

Concrete surface - ¾ sq. mtr. Per kg mix

Packing Resin Epoxy Resin / Coaltar Hardener is available in 200, 100, 50, 5, 1 kg packs Epoxy

Resin / Coaltar Hardener

Physical Characteristics :

Finish - Glossy

Color - Black

Substrates - Concrete / Metal

Components - 2 pack system

Cure - Solvent less and chemical reaction between 2

Components

Volume of solids - 50 %

Dry film thickness - 125 – 145 Microns per coat

No of coats - 2

Coverage - 4 Meter per kg mix

Mixing Ratio - 3 : 1

Pot Life - 30 Minutes

Setting Time - 2 hrs

Curing Time - 24 hrs

Application - By brush/roller/spray

Temperature resistance - Up to 150 degree Centigrade

Flash point - 96oC

On Resin

Thinner - Epoxy Thinner

Packaging

available in 20 kgs packs and has a maximum shelf life of 12 months in the un-opened condition

Handling & Safety

Observe reasonable care and employ ordinary hygienic principles such as washing the hands with soap and water

before eating or smoking. It is recommended to wear gloves, goggles and nose masks while application. Incase of

splashes on the skin, dampen the cloth with thinner and wipe the hands with the cloth. Wash then with soap and

water. Dried film is non toxic. Incase of contact with eyes, rinse with plenty of water and seek medical advice.

Incase of continuous exposure to vapours, the applicator should be immediately moved to get fresh air.

| Download to Safety Data Sheet |